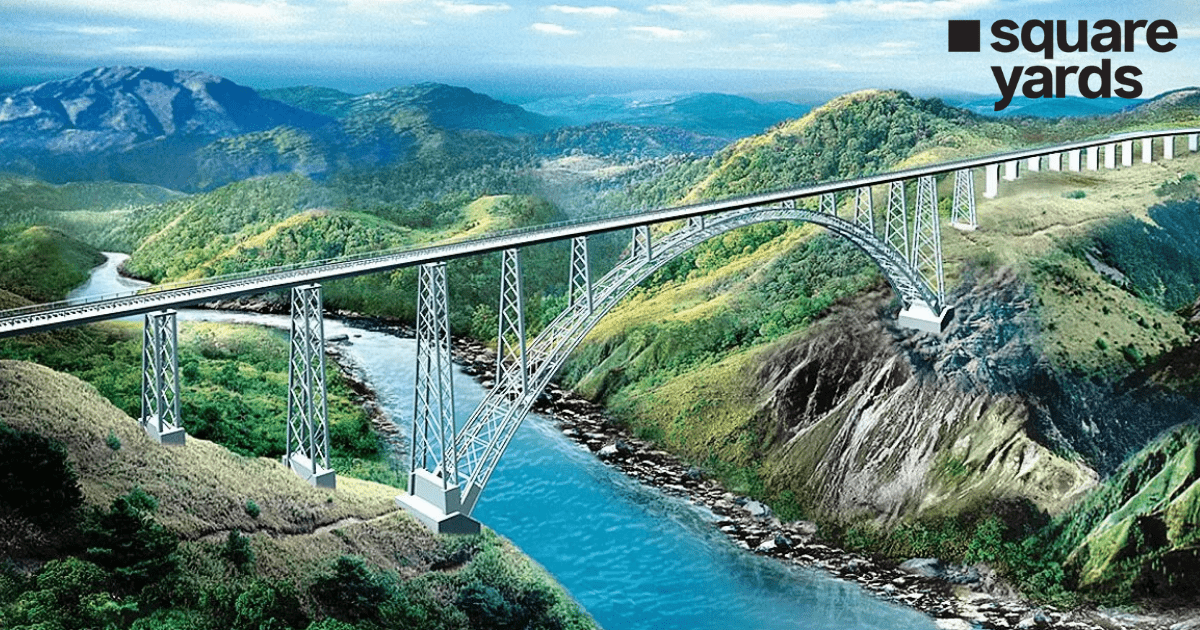

Standing at 1,178 feet (359 metres) above the riverbed, the Chenab Railway Bridge joins Bakkal and Kauri in Jammu and Kashmir’s Reasi district. The structure is of a steel-concrete arch bridge. The world’s highest railway bridge, it is a mamothian project of the Indian Railways. In 2017, the foundation supports of the Chenab River bridge were completed, which allowed the beginning of the main arch’s construction.

In this blog, let’s get to know about the Chenab Rail Bridge along with its various features, benefits and construction challenges.

How Was the Chenab Rail Bridge Constructed?

The idea of this stunning structure was born in 2004. The closure of the main arch was done recently, making the world’s largest bridge to be all set for connecting Kanyakumari to Kashmir. This iconic structure was included in the Indian Railways’ USBRL (Udhampur-Srinagar-Baramulla Rail Link) project.

Recently, a 5.6-metre-long piece of metal was fitted between the two arms of the arch, at the highest point of the Chenab bridge, making it the last metal contributing towards the Chenab Railway Bridge’s completion.

Almost three years later, after the Chenab Bridge’s construction began, the Indian Railway Minister, Piyush Goyal, tweeted about the world’s highest bridge, wherein he touted the structure as an infrastructural marvel.

Let’s see below how it was constructed.

- The segments of this bridge were constructed with a steel arch along with the adjournment of a cable crane that lifts about 35-ton blocks of steel in one go.

- The steel arch was constructed through the cantilever method.

- The halves of the bridge were hung on both ends of the cables and fixed to the structure’s base.

- The structure of this steel bridge will be inaugurated above the steel brace and will join in the centre of this arch from both directions.

- And, at last, the rails will get stationed on the track for the purpose of train traffic.

- One of the major challenges faced by the wind engineers for this project was not the size but the way the bridge’s site or altitude was placed.

- There was special tunnel testing done to evaluate wind parameters.

- Wind engineering for this bridge was established by accumulating in-house and wind tunnel experts of the force technology from Denmark.

- Next in line was the testing of the Standard Section Model, which played a major role in contributing to the aerodynamic input, which included

- WSPs Advancement

- 3D buffeting study (that was later confirmed through the aeroelastic model examination)

- Equivalent wind loads static extraction.

- There were frequent changes made in the designs and construction of the process that were assessed statistically.

- This bridge is not seen to be prone to any aeroelastic instabilities, all thanks to the foundation of the arch.

- Until now, the bridge has been free from experiencing any storm. Although, it is assumed to experience such storms in the course of these 120 years of bridge service.

- The setup of warning alarms and controlling the management of such wind conditions will act helpful for managing any rail traffic.

More Information on the Chenab Railway Bridge

The Chenab Railway Bridge revolved around the two factors of necessity and design. Let’s see how it affected both of them below.

Necessity

It has always been a tiresome thing to travel around the mountain regions of Jammu and Kashmir for tourists and the locals. Therefore, a transport facility for connecting Jammu and Kashmir with the other parts of India was imminent. This was when the idea of the Chenab Railway Bridge came up. The Indian Railways took up the project, which included the daunting task of building multiple tunnels in the challenging Himalayan terrains and bridges along the mountain route. The tallest bridge in India covers the span over the Chenab River, providing smooth mobility from the Kashmir valley to the district of Udhampur.

Design

The Chenab Railway bridge is the country’s first bridge to form a massive steel arch. Similar rail bridge projects from other countries inspired the design of this stunning structure. The Chenab River valley is an area prone to high wind pressures. Keeping in mind this risk factor, the Chenab Rail Bridge has been designed for resisting wind speeds of 260 kmph. Also, the deep valley under the Chenab Bridge is a Seismic Zone IV susceptible to devastating earthquakes. It was, therefore, ensured that this rock-solid structure was strong enough to withstand an earthquake of 8-magnitude.

Interesting Facts about the Chenab Railway Bridge

Given below are some interesting facts on the Chenab Railway Bridge.

- The total cost estimated of the Chenab rail bridge is Rs 1,486 crores.

- The Chenab bridge covers a total length of 1,315 metres.

- There are 17 spans in total over the Chenab Rail Bridge.

- The life of the Chenab Railway bridge is 120 years.

- Trains are allowed to pass across the Chenab bridge at a maximum speed of 100 kilometres/hour.

- The highest bridge in India has been designed by consulting DRDO (Defence Research and Development Organisation).

- The Chenab Bridge is designed to withstand wind speed up to 266 kilometres/hour.

- It is designed to bear earthquakes of up to 8 magnitudes.

- For joining the different parts of the bridge, approximately 584km (Jammu to New Delhi) of welding has been done.

- For the first time, the Indian Railways have launched the curved viaduct portion by using the method of End-launching.

- Warning and health monitoring systems have been extensively planned through state-of-art instrumentation.

- Srinagar’s cable crane pylon stands at the height of 127 metres, making it higher than Delhi’s Qutub Minar (72 metres).

- For testing the welds, a phased array ultrasonic machine has been used by the Indian Railways for the first time.

Features of the Arch of the Chenab Bridge

Here are some of the features of the spectacular arch of the Chenab River Railway Bridge.

- The Chenab River bridge is 35m higher than the world-famous Eiffel Tower in Paris.

- The arch is made by using boxes of steel. The boxes will be stuffed with concrete to improve stability.

- The arch of the Chenab River bridge weighs 10,619MT.

- A first in the Indian Railways history, the members of the arch were erected by using overhead cable cranes.

- The construction of the Chenab River Rail Bridge involved the usage of 28,660 Meta Tons of steel.

- For structural detailing of the Chenab River bridge, Tekla software has been used.

List of Contractors Involved in the Chenab River Project

Below is the list of the contractors who were actively involved with the Chenab River Project.

| Department | Name of Project Contractor |

| Foundation Protection Designer | Indian Institute of Science (IISc), Bangalore |

| Slope Stability Analysis | Indian Institute of Technology (IIT), Delhi |

| Executing Agency | Konkan Railway Corporation Ltd. |

| Seismic Analysis | Indian Institute of Technology (IIT), Delhi & Roorkee |

| Proof Consultant for Foundation and Foundation Protection | M/s COWI, UK |

| Arch Designer | M/s Leonhart, Andra and Partners (Germany) |

| Viaduct and Foundations Designer | M/s WSP (Finland) |

| Executing Agency | Konkan Railway Corporation Ltd. |

Challenges Faced while constructing the Chenab Railway Bridge

Here are the challenges faced while constructing the Chenab Railway Bridge.

- The rugged and mountainous Himalayan terrain posed a threat to the construction of the Chenab Rail Bridge. 900 metres tall cable cranes were installed on both sides of the Chenab gorge to build the arch of the bridge.

- At such a high altitude, the bridge construction was festered with winds up to 50-60 kmph. The construction work was also hampered because of frequent and unprecedented rains, thunderstorms, landslides and snowfall.

- This is why assembling the arch showcased the great work projection of the engineering skill.

- Work on the arch construction started back in 2005. It was only finally linked after 16 years in March 2021.

- Analysis for tunnel construction and earthquake also posed a challenge due to the persisting winds and the treacherous terrain.

Frequently Asked Questions (FAQs)

Q. Is the Chenab Bridge ready?

The world’s highest bridge, the Chenab Railway bridge, is ready. In 2017, the foundation supports of the Chenab River bridge were completed, which allowed the beginning of the main arch’s construction.

Q. Is Chenab Bridge the highest rail bridge in the world?

Standing at 1178 feet (359 metres) above the riverbed, The Chenab Railway bridge is the world’s highest bridge.

Q. Is the Chenab bridge operational?

The Chenab railway bridge will be operational by the year 2022. The world’s highest railway bridge belongs to the Indian Railways.